Description

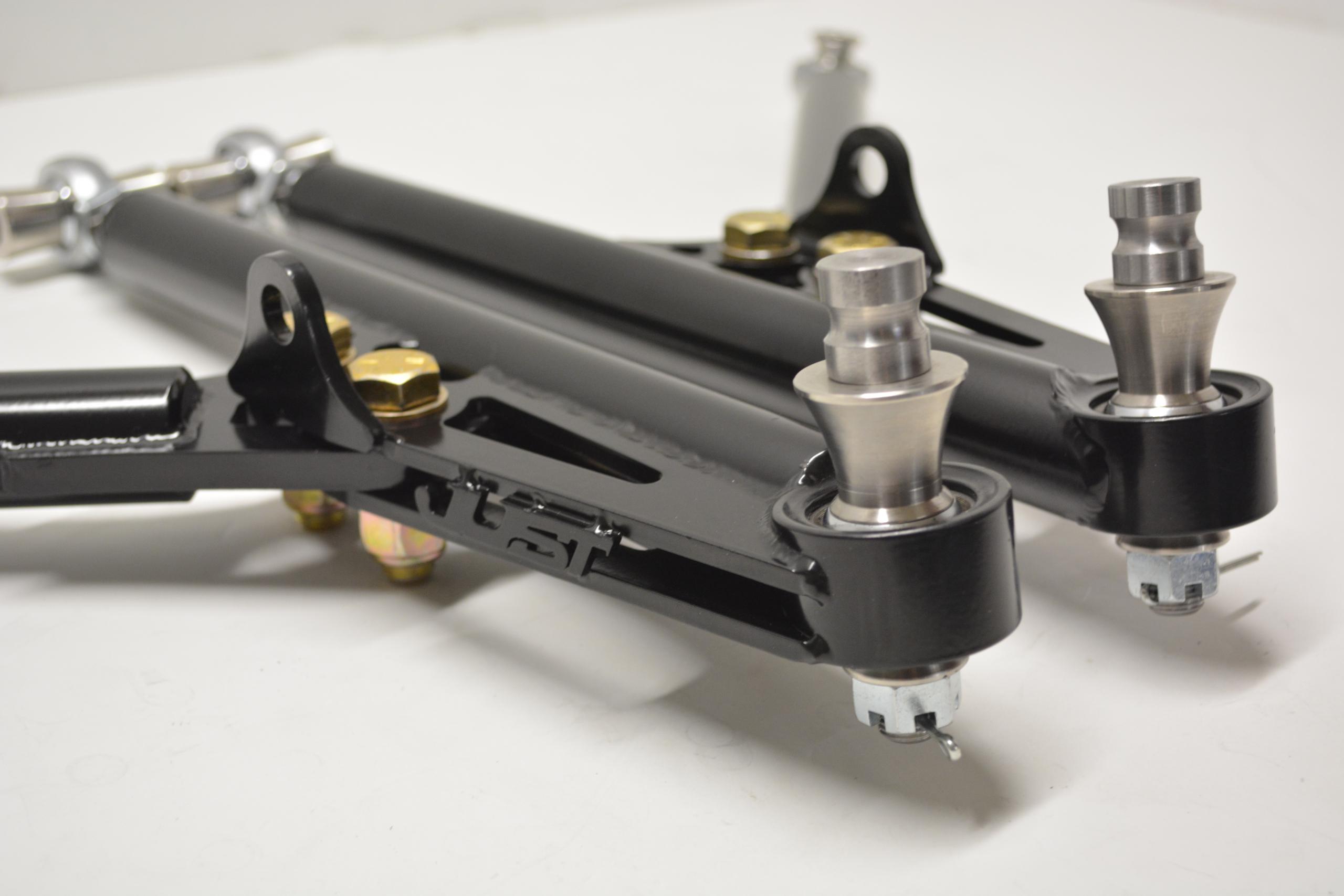

Full Chromoly construction with tubing and raw stock from the USA, these arms have 1/2” (12mm) of roll center correction and are purely designed for the track. Engineer designed ball joint : welding a ball joint stud isn’t a practical option. We have taken into consideration previous competitor designs, and found, with the help of structural analysis, that the entirety of the load subjected through the ball joint shaft hadn’t properly been taken into consideration. Our design eliminates all possibility of ”flex” at the junction of the knuckle. We also came up with this rebuildable ball joint with a precisely machined Chromoly shaft.

- Heavy duty Chromoly rod end and ball joint spherical bearing

- Rebuildable ball joint that allows you to adjust the roll center to your need with some simple modifications

- American premium 4130, 1.25” (31mm) diameter Chromoly steel tubing

- Fully adjustable on both camber and caster

- Sturdy design at the junction of the trailing and main arms with two 1/2” graded bolts

- Zinc plated steel rod end spacer/reducer

- In-house powder coating for a better result

- Stubby weld bung at the rod ends for added strength and minimized long term stress on the weld

- Proper support material around ball joint bearing cup

- High strength Chromoly ball joint shaft coupled to a high load capacity bearing

- Requires a Just Engineering sway bar link

- Double threaded adjuster available on demand, please contact us directly

*LIFETIME WARRANTY ON CRAFTSMANSHIP… you won’t have a weld failure!